AD P500

High Performance PU Synthetic Membrane

Description

AD P500 is a single-component UV-resistant elastic liquid-applied, crack-bridging waterproofing compound. Suitable use onto concrete slabs, balconies, horizontal walls and etc.

AD P500 adheres to almost all kinds of mineral substrates such as concrete roof slabs, gutters, terraces, external wall and facade, and metal roofs

andetc

Product Properties

- Single-component, ready-to-use

- Eco-friendly with low VOC / Non-toxic

- High bond and high elastic properties

- Easy and quick application

- UV-Resistant designed for exposed radiation

- Crack-bridging properties

- Can be used on horizontal and vertical surfaces

Area of Application

- Concrete roof slabs and gutters

- Balconies and terraces

- External walls and facades

- Metal roofs and car porch roofs

Substrate preparation

The substrate must be structurally sound and free from cement laitance, loose particles, dust, oil, grease and any other contaminants or old coatings which may affect the adhesion. Grind smooth all high spots and sharp protrusions. Surface defects such as honeycombs and cracks must be repaired and re-profiled to prepare a sound surface for bonding. All right-angle and 90 degrees bends must apply AD SST 150 System Sealing Tape or a mortar angle fillet Horizontal substrates to receive AD P500 must have sufficient gradient to avoid water ponding on the membrane.

Mixing

- AD P500 is supplied ready to use. Mix thoroughly with a low-speed mechanical mixer prior to application for color homogenization.

Product Properties

Standard System

- Primer mixing AD P500 +10% clean water. Apply at the rate approx. of 0.4 kg/m2

- Once the priming coat has dried after approximately 1-2 hours, apply the first neat coat of AD P500 by brush, roller or spray equipment at the rate of 0.5 kg/m2 . After 4 to 6 hours curing time, depending on the ambient conditions, apply the finish coat at the rate of 0.5kg/m2 but in a crosswise direction.

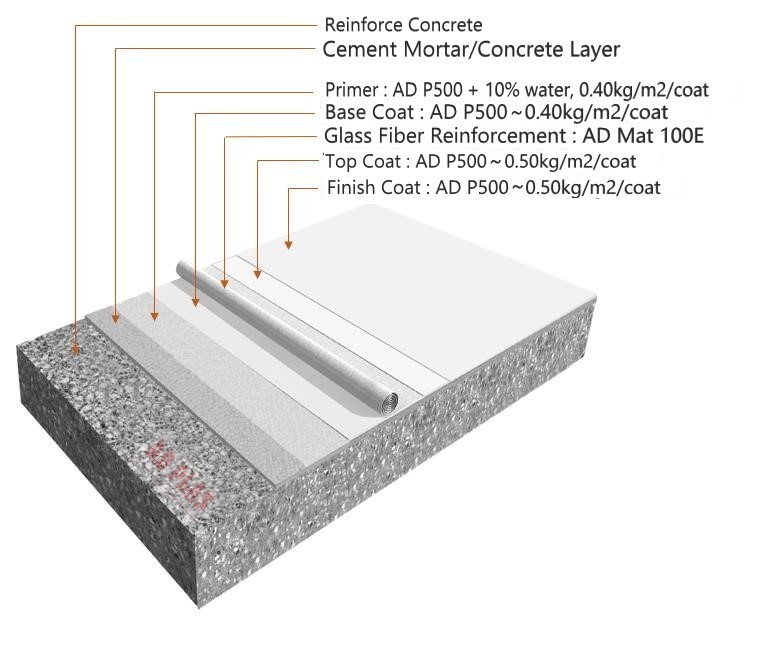

Heavy Duty System

- Primer mixing AD P500 +10% clean water. Apply at the rate of 0.4 kg/m2

- Once the priming coat has dried after approximately 1-2 hours, apply the first neat coat of AD P500 by brush or roller at the rate of 0.5 kg/m2. Following this, lay a layer of reinforcement AD MAT 100E fibremesh onto the wet coating and embed it to thoroughly impregnate the mat. Make sure there are no air bubbles or creases.

- After a curing period of 2 to 4 hours, apply the next two neat coats in a crosswise direction to the previous coat. The material consumption is 0.5 kg/m2 /coat and the overcoating time is around 2 to 4 hours, depending on the ambient conditions.

Protection and Curing

The freshly applied membranes must be protected from rain for a minimum of 4-6 hours. Full cure of AD P500 waterproofing system is minimum 72 hours after the final coat. Ponding test may be carried out after full cure.

Remark

Waiting time between layers above are based on 20-30 degree Celsius with 50% relative humidity.

Do not apply on the moisture substrates

Do not apply on during rising temperatures

Technical Data

- Density: 1.40 kg/litre

- Pot Life: 1 hour (once opened)

- Curing Time: 36 hours

- Consumption:1.4 kg/m² (Standard System ~0.5mm per coat)

- Consumption:0.4 kg/m² (Heavy Duty System)

- Consumption:0.5 – 0.7 kg/m²

Product Characteristics

- Packaging: 20 kg plastic bucket

- Colors: Grey

- Storage: Can be stored in shaded, cool, and dry conditions for 12 months in original unopened packs

Video

Media Gallery

Before